Painting Corrugated Steel

Dip a clean rag into your soap solution then wring it out.

Painting corrugated steel. It also has surface contaminants oils greases residues etc left on the surface from the manufacturing process that interfere with the adhesion of paints. New galvanized metal a product used to make corrugated sheets gutters and downspouts is usually smooth and is coated with either a layer of oil to prevent white rust or is passivated. Use a power washer or brush with a mild cleaner to remove grime and debris. You can also use oil based alkyd paint but.

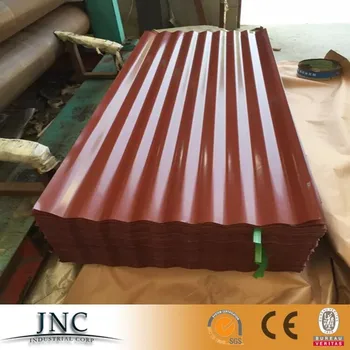

Mix 1 tablespoon dish soap and 1 gallon of water in a bucket to create a soap solution. Corrugated metal sheet is a tough light weight and weather resistant material that provides advanced protection qualities that cannot be matched by any other type of material. Painted metal roofs come with a baked on factory finish and you can re coat these as well as paint bare metal roofing with acrylic latex paint. Prepare and paint metal building including some masonry areas.

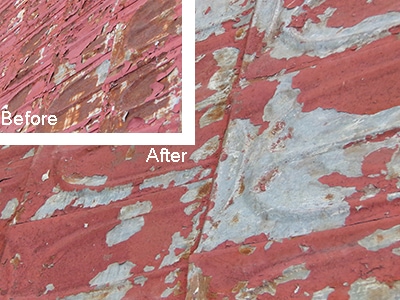

Spray down the corrugated metal with water from a hose. Use the ladder for painting the steel siding on the top and using the roller paint in a horizontal direction. Step 2 maintain the roof. The first trick to corrugated metal roof is to not paint a dirty metal roof.

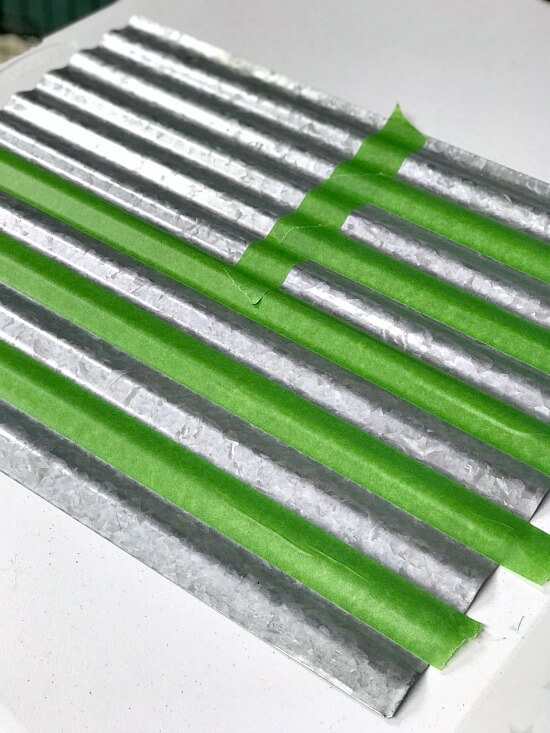

A fresh coat can liven employee spirits and a new color scheme can even serve to reinvent a companys image. Due to its innate high grade quality metal corrugated panels are extremely resilient manufacturing materials that provide numerous benefits to a wide range of. The problem with painting galvanised metal is that the surface when new is very shiny and smooth making it difficult for paint to stick to the surface. Before applying a new coat of paint you need to get rid of any oil debris and dirt buildup that already exists.

Paint applied over this oily surface or clear passivator will peel quickly. Wash the corrugated metal with the soap solution wetting the rag as often as needed.

.jpg)